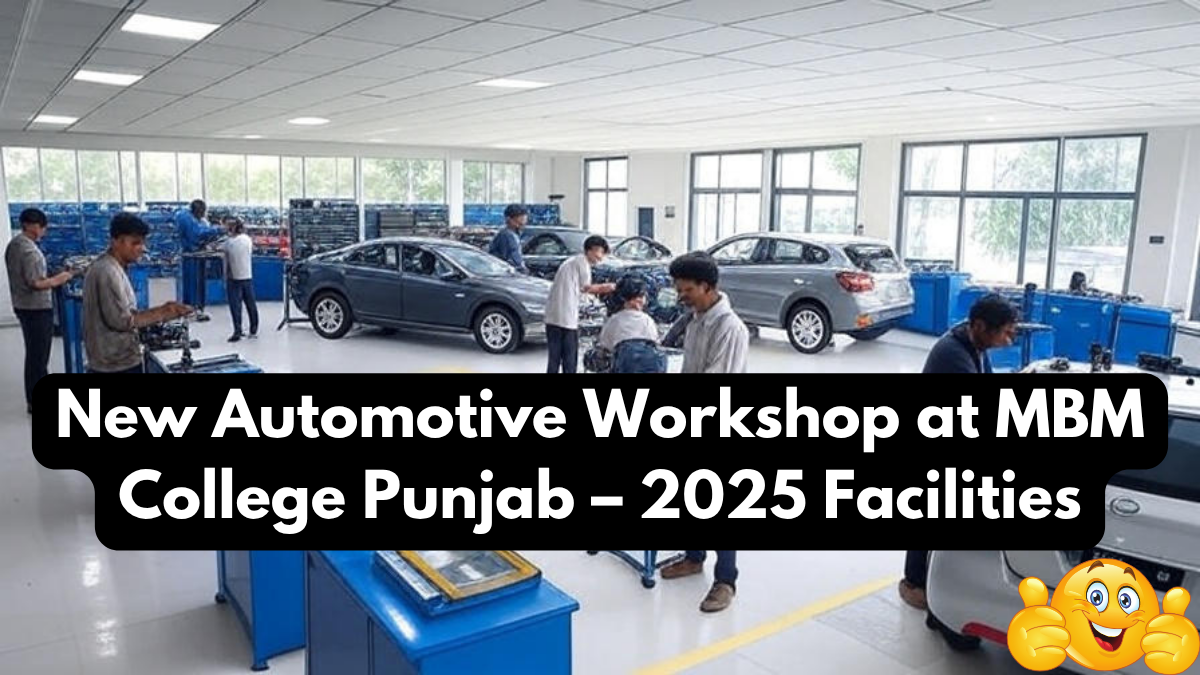

Practical hands-on experience has become essential in technical education, especially in automotive engineering. With this in mind, MBM College has introduced state-of-the-art upgrades to its Campus Auto Workshop Facilities PWB. This revamp is part of a broader initiative to provide students with cutting-edge exposure to real-world technologies, tools, and working conditions.

The 2025 overhaul aligns with the evolving trends in mobility and mechanical innovation. MBM College’s new automotive lab infrastructure aims to give students a deeper understanding of vehicle systems, diagnostics, repairs, and modern manufacturing methods. This facility upgrade reaffirms MBM’s reputation as a leading institution in technical education across Punjab and beyond.

Highlights of the Upgraded Campus Auto Workshop

The newly renovated Campus Auto Workshop Facilities PWB at MBM College are built to bridge the gap between theory and application. Students pursuing automotive engineering now have direct access to the same diagnostic and servicing equipment used in modern auto shops and service centers.

Some key features of the upgraded automotive lab infrastructure include:

-

Hydraulic lifts and wheel alignment stations

-

Engine dismantling and assembly sections

-

Advanced battery testing units

-

EV component display and repair bays

-

3D engine models for training purposes

-

Fully digital diagnostic and OBD-II scanning systems

-

In-house fabrication tools and welding stations

These upgrades enhance students’ ability to work with both traditional internal combustion engines and next-gen electric vehicles.

Overview of Campus Auto Workshop Facilities

| Facility Feature | Description |

|---|---|

| EV Component Bay | Dedicated area for electric motor, controller, and battery systems |

| Engine Rebuild Zone | Includes equipment for dismantling and assembling engines |

| Diagnostic Lab | Features OBD-II scanners, oscilloscopes, and real-time data tools |

| Fabrication and Welding Shop | Offers MIG, TIG, and arc welding equipment |

| Suspension and Steering Station | Helps students understand chassis alignment and suspension tuning |

| Digital Training Aids | 3D engine models, AR tools, and simulation software |

The integration of such tools within the automotive lab infrastructure ensures that MBM College students gain technical mastery through a hands-on approach, well before entering the industry.

Preparing Students for Industry Standards

As the automotive industry transitions toward electrification, automation, and smarter systems, educational institutions must prepare students accordingly. MBM College recognizes this responsibility and has realigned its workshop structure with futuristic goals.

Students at the upgraded Campus Auto Workshop Facilities PWB will work on real-time repair simulations, electric drivetrain setups, and embedded system installations. This not only improves their practical knowledge but also boosts employability.

Moreover, MBM’s new automotive lab infrastructure allows project-based learning in collaboration with industry mentors, fostering innovation and problem-solving skills. Final-year students also get access to capstone projects, which often lead to internships and job offers.

Future-Focused Learning Environment

The transformation of MBM’s automotive labs isn’t just about equipment. The college has also appointed specialized instructors, many with industrial experience, to mentor students. This mentorship adds a deeper layer of understanding to the already advanced technical exposure.

Weekly practicals, live demonstrations, industrial visits, and student workshops are now regular parts of the curriculum. Students in the Campus Auto Workshop Facilities PWB can now visualize every theoretical concept in real time using actual vehicles and prototypes.

The new space also promotes collaborative learning through team-based assignments, system diagnostics competitions, and vehicle teardown exercises. This reinforces MBM’s mission to produce industry-ready graduates through hands-on training and the best automotive lab infrastructure available in the region.

Conclusion

The 2025 upgrades to MBM College’s Campus Auto Workshop Facilities PWB have set a new benchmark for engineering institutions in India. With immersive learning environments, digital integration, and top-grade mechanical tools, MBM students now enjoy unmatched practical exposure. These enhancements to automotive lab infrastructure make MBM College an ideal choice for aspiring automotive professionals who want real-world experience during their academic journey.

FAQs

What’s included in the new Campus Auto Workshop Facilities PWB at MBM?

The new workshop includes engine labs, EV testing zones, diagnostic tools, fabrication shops, and suspension alignment setups.

How does the new automotive lab infrastructure benefit students?

It offers hands-on learning with industry-standard tools, enabling students to gain real-world skills before graduation.

Is the workshop used by all engineering streams?

Primarily, it is designed for automotive and mechanical students, but interdisciplinary sessions are also held.

Are external certifications provided through the workshop?

Yes, MBM partners with training bodies to provide optional skill certifications in diagnostics, EV maintenance, and welding.

Does the college offer projects using the new lab facilities?

Yes, students are encouraged to conduct final-year projects and live demonstrations using the latest equipment in the workshop.

Click here to learn more